Rbertalotto

Well-known member

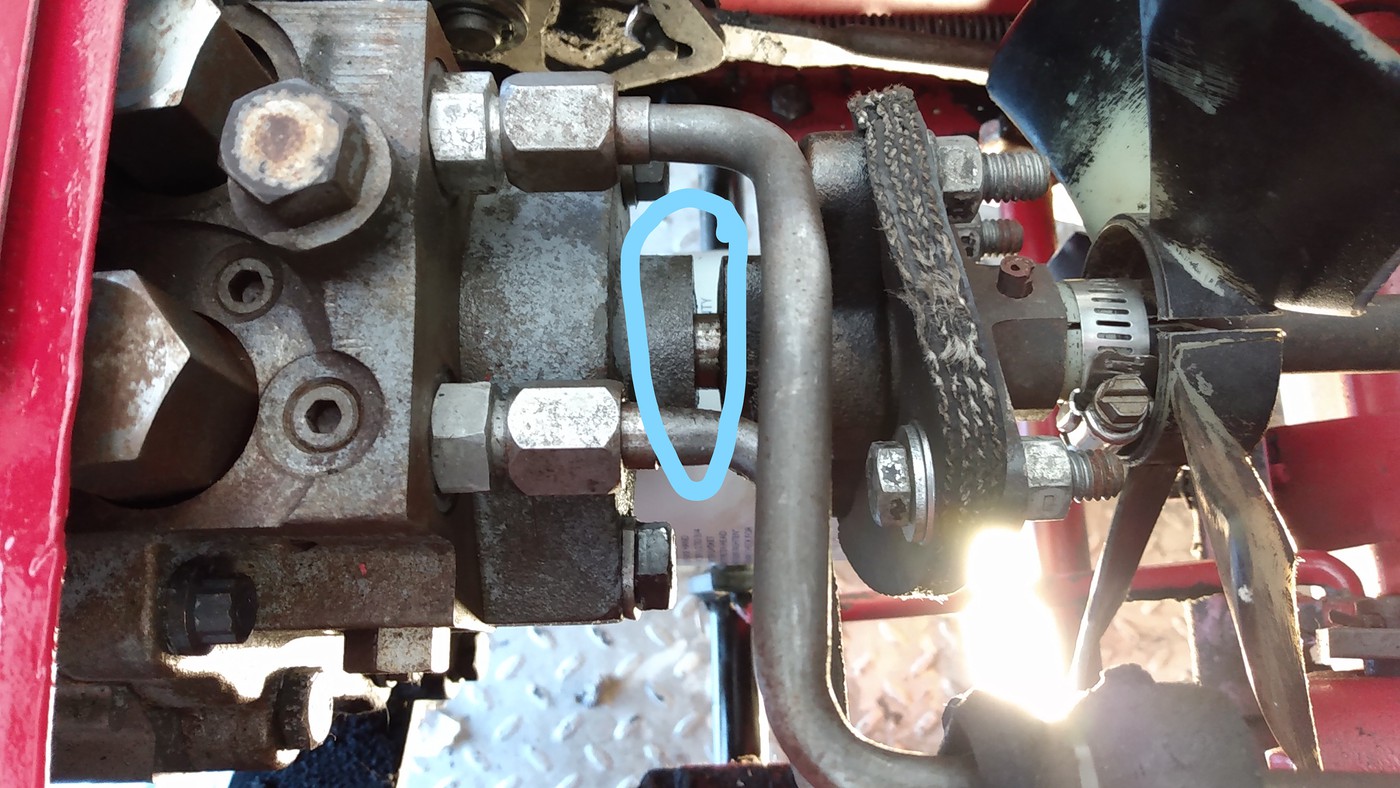

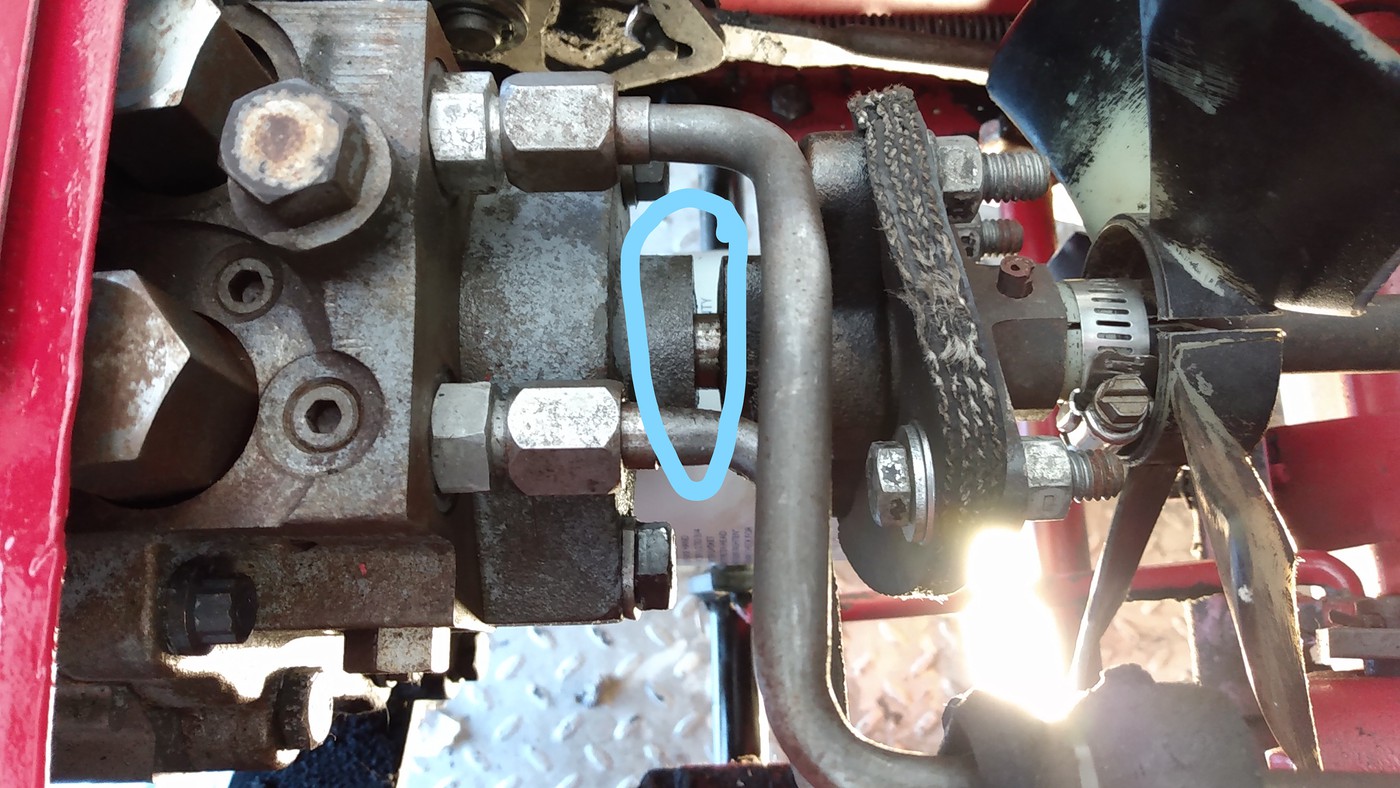

It is leaking from the seal around the input shaft right after the fiber driveshaft joint.

How difficult is it to replace this seal? Any "How To" videos or other info around?

How difficult is it to replace this seal? Any "How To" videos or other info around?